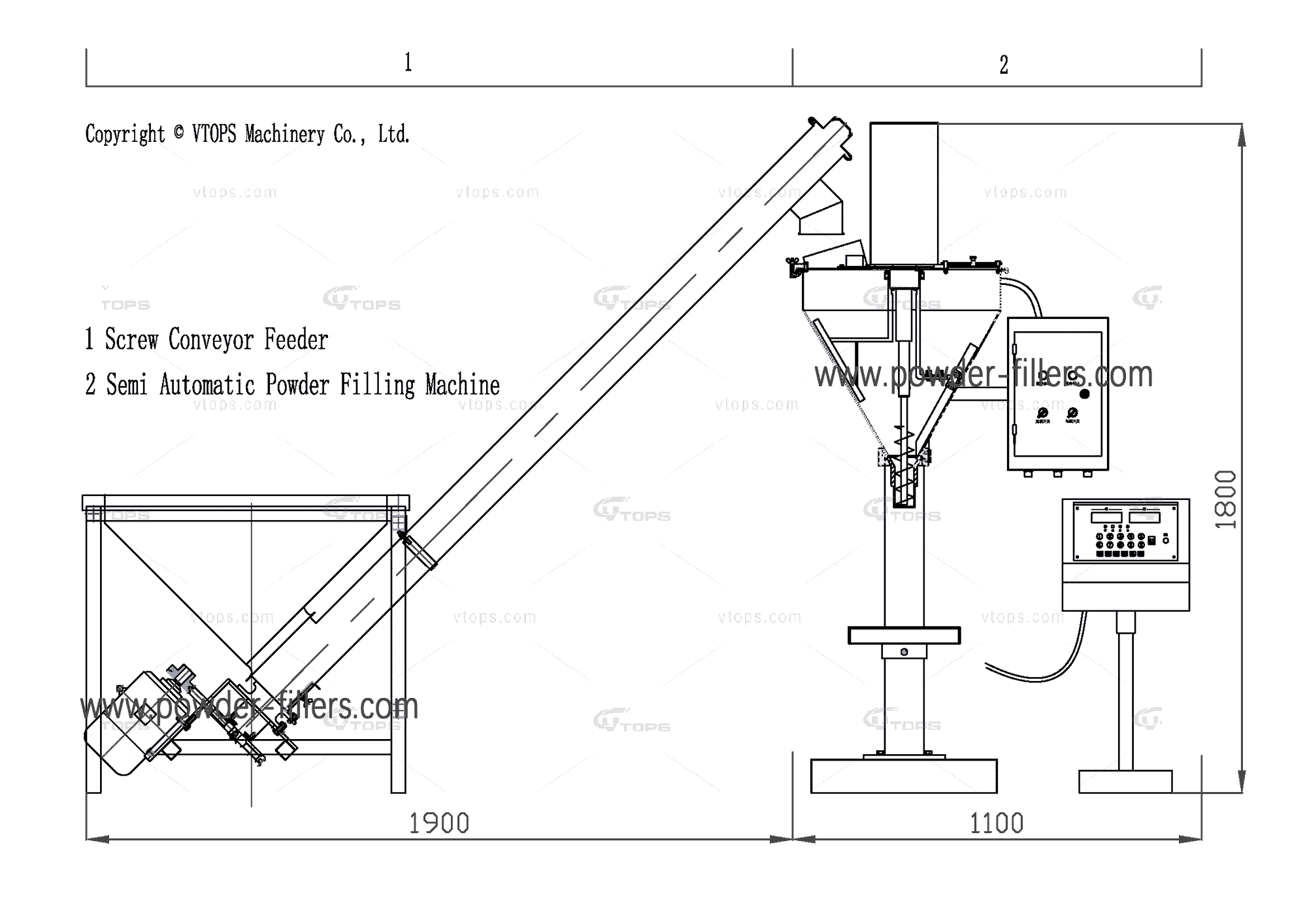

Image Description: The Design Drawing of 5 – 5000 grams Semi-Automatic Dry Powder Auger Filling Machines.

Image Description: The Design Drawing of 5 – 5000 grams Semi-Automatic Dry Powder Auger Filling Machines.

How many the types of Semi-Automatic Dry Powder Auger Filling Machines?

Semi-Automatic Powder Filling Machine

Model: UA-P1

Filling Weight: 5g – 5000g

Measurement Method: Auger Filler

Filling Accuracy: ± 1%

HMI: Keyboard

Control System: SCM (Single Chip Microcomputer)

Filling Motor: Stepper Motor

View More

Semi-Automatic Powder Filling Machine With Touch Screen

Model: UA-P2

Filling Weight: 5g – 5000g

Measurement Method: Auger Filler

Filling Accuracy: ± 1%

HMI: LCD Touch Screen

Control System: PLC (Programmable Logic Controller)

Filling Motor: Servo Motor

View More

What is the difference between Semi-Automatic Dry Powder Auger Filling Machines?

- Brand

- Measurement Range

- Applicable

- Measurement Method

- Filling Accuracy

- Filling Speed

- Contact Materials

- HMI

- Control System

- Filling Motor

- Level Monitoring Hopper

- Voltage

- Power

- Dimensions

How How does a Semi-Automatic Dry Powder Auger Filling Machine work?

Why do different of filling weight require different diameter Augers?

Different filling weights change different diameter Augers in order to increase filling accuracy and filling speed.

For example:

We are familiar with the water faucets and their diameters have a difference.

A water faucets with thick diameter have a fast flow rate, but have poor accuracy.

A water faucets with thin diameter have a slower flow rate, but have higher accuracy.

So, our solution (Diameter of Auger Fillers)is following: