A Semi Automatic Powder Filling Machine Successfully Delivered for New Zealand Client

This week, a set of Vtops’s Semi Automatic Powder Filling Machine and Screw Conveyor Feeder (Powder Feeding Machine) arrived in Auckland of New Zealand by sea. It took less than 20 days since the Client approached Vtops for product inquiry.

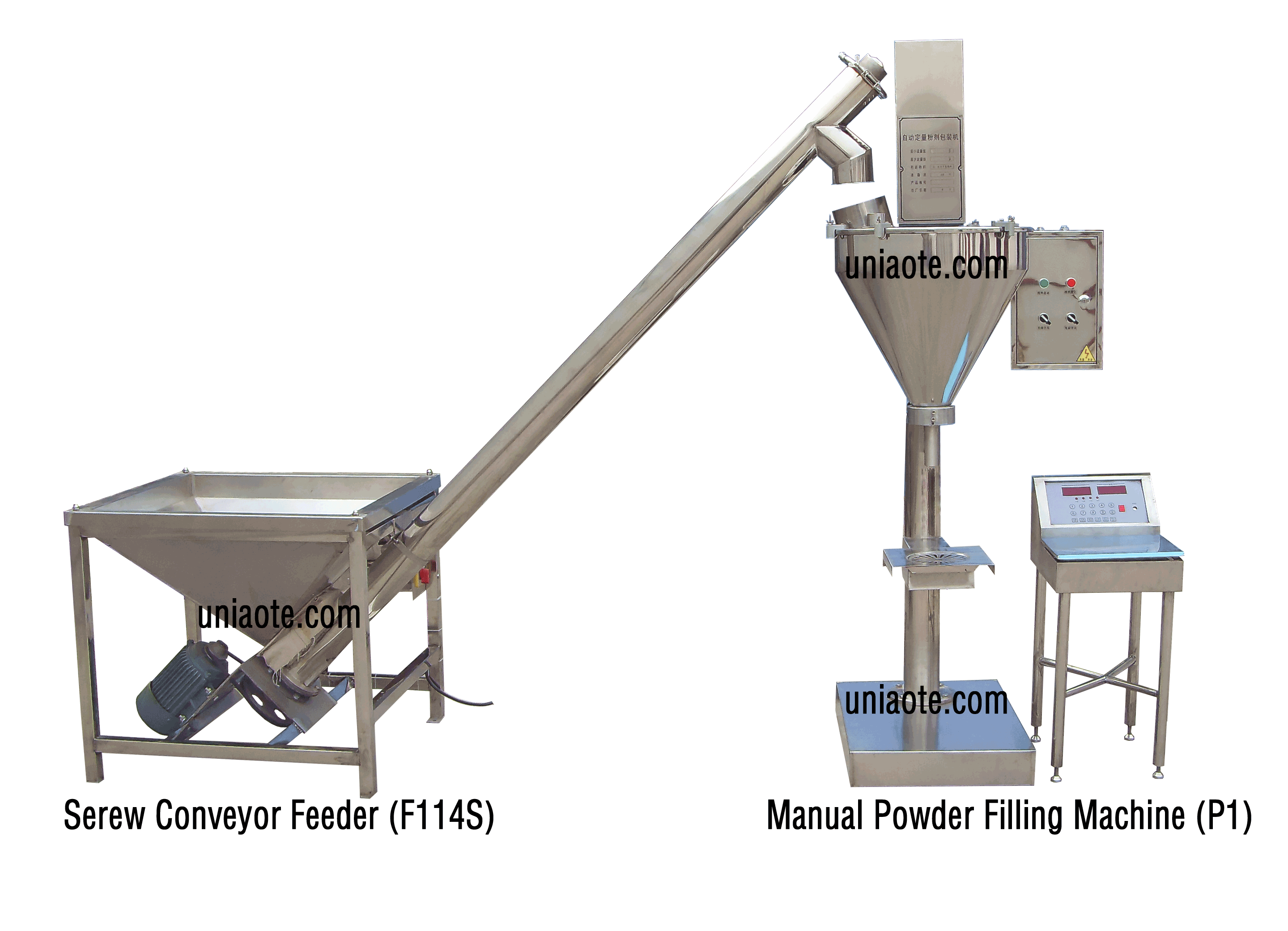

Image Description: Screw Conveyor Feeder (Model:UA-F114S) + Semi Automatic Powder Filling Machine (Manual Powder Filling Machine) (Model:UA-P1)

Image Description: Screw Conveyor Feeder (Model:UA-F114S) + Semi Automatic Powder Filling Machine (Manual Powder Filling Machine) (Model:UA-P1)

Established in 2001, Vtops is an experienced designer, manufacturer and exporter of all kinds of powder filling machines. The company’s products and brand name are well received on Alibaba platform, with sales increasing constantly and well ahead of peer companies.

This Powder Filling Machine was ordered by a renowned brewing equipment group. It is based in New Zealand and manufactures Australasias largest range of distilling ingredients and equipment. It is also the world’s largest manufacture of beer kits and owns breweries throughout Australia.

A Fast and Smooth Process

The client contacted Uniaote on March 9 and decided to buy the machinery set after brief inquiry. They believed the products are satisfactory and within budget. Three days later they paid in full.

“This category is conventional and we have inventories, so we don’t have to keep client waiting,” Taka Chang, International Trade Director at Uniaote, says. “We arranged shipment in a short time and the machines was sent to port within 3 days. The whole process is very smooth.”

Uniaote’s Semi Automatic Powder Filling Machine adopts screw electronic weighing measurement mode feedback combining computer control, with automatic quantitative, automatic filling and other functions. It is suitable for condiments, natural flavoring, food additives, flavors and fragrances, flour, milk powder etc.

The machine is easily operated and highly efficient with stable performance. See video below:

Pay attention to details

Uniaote designs and manufactures fully automated powder, granule and liquid product filling machines. The company is a well-established packing and filling machinery manufacture with a complete suite of production lines, including automatic, semi-automatic and manual solutions.

Preservative-treated of Motor Drive Wheels

As a professional manufacturer and with more than 16 years of experience in the industry, Uniaote’s filling machines are of the best standard. For example, the whole machine delivered uses SUS304 stainless steel. Untouchable parts, such as motor drive wheels, are made by cast iron and preservative-treated.

Global demand for packaging of food and drink products has created substantial market opportunities for filling machines companies. Uniaote’s packing and filling machines are winning increasing attention from international companies but not only because of its superb quality. “Uniaote pays attention to detail and what customers want and need.” Chang said.

The client required electric voltage of single-phase 230V 50hz, a parameter for ordinary residence in New Zealand. “Our engineer adjusted the machine to meet the voltage requirement of New Zealand Client. So that it can be used for extended longevity. Moreover, we give the client low price for delivery to Auckland of New Zealand by sea. Voyage only 17 days!”

Future Cooperation

In the past six months, three sets of fully-automatic powder filling production lines delivered to Australia, and a fully-automatic auger powder filling production line exported to Germany, a fully-automatic auger powder filling production line to Malaysia. But not only powder filling machines.

Chang believes the latest purchase is another demonstration of the popularity of Uniaote’s products and further orders will come as a result of brand reputation and services. “Clients will come back to us with more orders. We provide quality products and perfect after-sale services. There will be product upgrade and scaling up, so we are expecting more cooperation with our clients in the future.”

Product Information:

Features:

- Suitable for all kinds of bottles, cans, bags of quantitative filling packaging container is not restricted.

- Filling motor is a stepper motor or servo motor.

- Stirring motor imported from Taiwan, free-noise motor.

- Photoelectric sensor induction signal filling material, can also optional foot switch signal.

- Feedback value can be adjustable, to meet a variety of precision required.

- The filling motor speed can be adjustable, to meet the requirements of various materials.

- All stainless steel, match with feeder enables automatic materials level control.

Features:

- Match up to the packing machines and filling machines, controlled by the packing machine or filling machine.

- Set the switch is provided with a return material, easy to clean material.

- Hopper provided with vibrators, feeding unhindered.

Related Links:

- 1. The Design Drawing of Semi Automatic Powder Filling Machine ;

- 2. The Working Video of Semi Automatic Powder Filling Machine;

- 3. The Component List of Semi Automatic Powder Filling Machine (Model: VTOPS-P1);

- 4. Fully-Automatic Powder Filling Production Line Installed for New Australian Client.