Considerations When Choosing an Automatic Powder Filling and Capping Machine

The purchase of an Automatic Powder Filling and Capping Machine for your business setup needs to be well planned and executed. This is because it has the potential of affecting business operations in the future. To ensure that you get it right, you have to thoroughly examine your operational, productivity and financial issues before making the purchase. In addition to that, you will also have to do an assessment of your future requirements which is more or less where you want your business to be in the next few years.

The automatic powder filling and capping machine is an essential part of many businesses of powder packaging industry. Purchase this equipment and install it in your plant, it is a smart investment for labor and productivity. However, there are several factors that you need to consider to ensure that you purchase the right equipment for your plant.

1: Configuration

One of the aspects that need your consideration is the configuration of the equipment. It is important to have this in mind especially if you are planning to change your production rate in the future. You might need high stringent reject rates and adequate speed that will meet your new demands. The capper modular for the capping machine needs to be able to adapt to your predicted future needs.

2: Inline or Monobloc

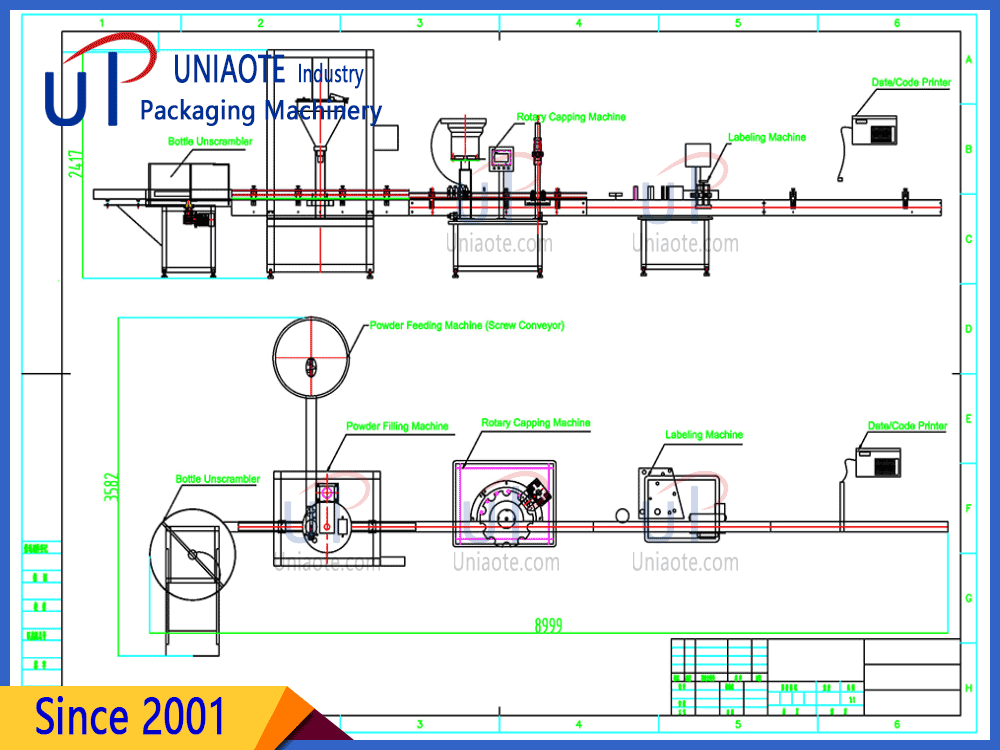

You will also need to make a choice between inline and monobloc when buying the automatic powder filling and capping machine. These are the two options that are available depending on how you want to complete your setup. The monobloc will occupy less space but its parts are more expensive as opposed to the inline equipment which occupies more space.

3: Caps

You will need to look at the range of caps and containers that the machine can use. There are different requirements from different clients because of the nature of operations that they conduct. This means that, you can either go for a single cap dedicated machine, or one that offers a wide range of packaging options. And, you will also need to consider the caps size, and the supported output speed.

4: Evaluate

The automatic powder filling and capping machine will have specific container and cap tolerances. This is an important consideration that you cannot afford to overlook together with the container quality. You can test and evaluate to ensure that the machine will produce as quoted. When the process is automated there is less tolerance issues with the caps or containers.

5: Durability

Order an automatic powder filling and capping machine needs to be looked into the economic aspect. You need to see the performance in comparison with its initial price. You can compare their cost for different speeds. Choose the best for you.

When looking into these factors, check them against your current and future needs. You should also put the cost of operation throughout its lifespan into consideration. The parts will wear with time and will require replacement at some point. The parts need to be affordable together with the consumables that will be required for operation. You can purchase the right equipment for your plant after you can assure all these in mind.

Tips:

- Your can send the containers and caps to the machines manufacturer before order. The machines manufacturer factory has some sample machines in stock, you can ask them to give you a test for your samples.

- Let the manufacturer shoot a complete video for you, before pay the balance or before deliver. Because in the manufacturer factory, the minor changes can be accept.