Fully-Automatic Powder Filling Production Line Installed for New Australian Client

In March, Uniaote engineer Lizhi Sun went to Australia and help a client, which is one of Australia leading health supplement manufactures, with installation and commissioning of fully-automatic powder filling production line for pet jars. The client contacted Uniaote in September and placed ordered in October last year.

-

Automatic Powder Filler Filling Machine for PET Jars

Automatic Powder Filler Filling Machine for PET Jars

Automatic Powder Filler Filling Machine for PET Jars

-

Automatic Powder Filler Filling Machine for PET Jars

Automatic Powder Filler Filling Machine for PET Jars

Automatic Powder Filler Filling Machine for PET Jars

Uniaote Success in Australia

Australia is well known for its high-quality milk powders, albumen powders, health food and supplements and there is great demand from overseas market for various types of products, especially from Asian markets. Facing with increasing export orders, local manufactures are in need of advanced and reliable packaging machinery to replace old ones or take production line in-house so as to improve productivity and operational efficiency.

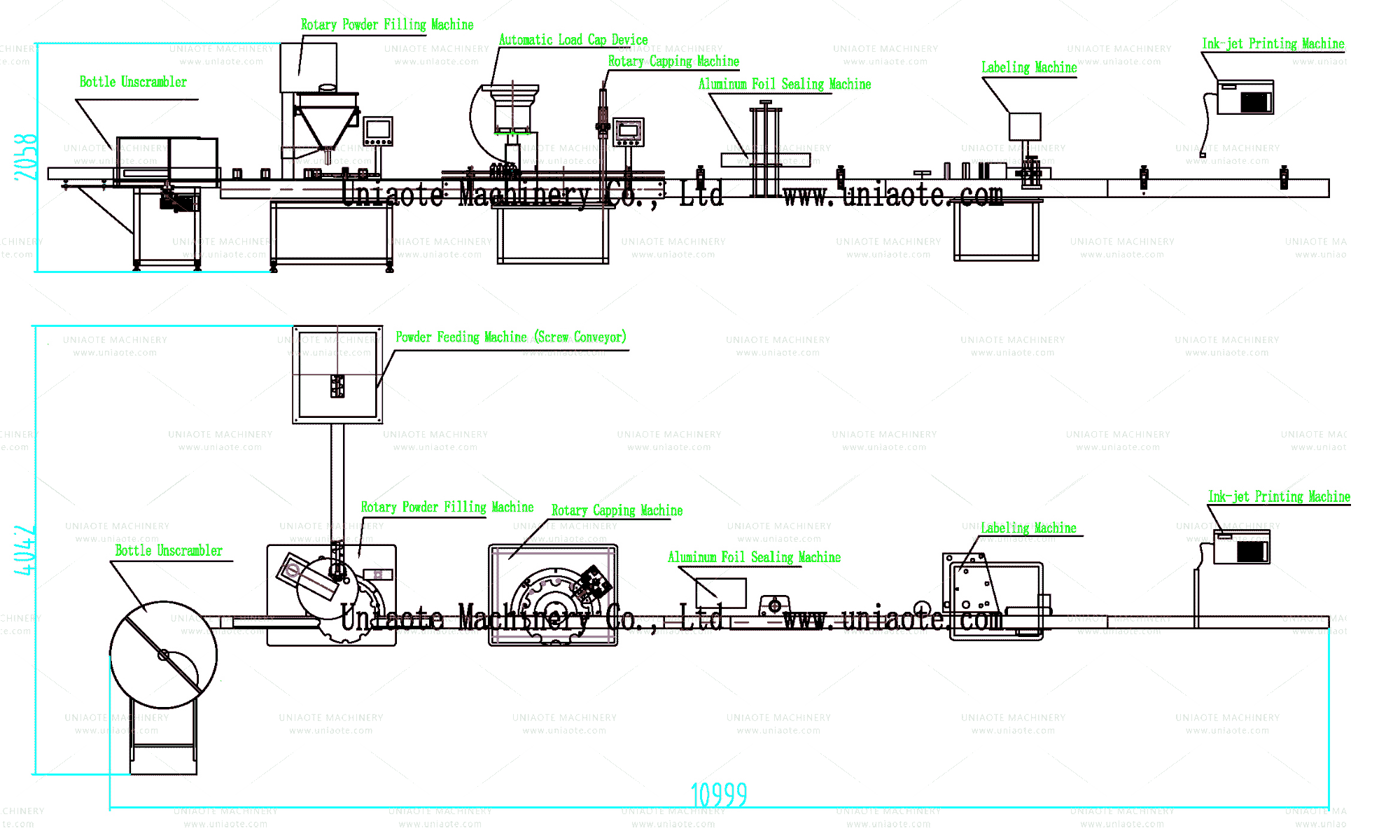

Uniaote brand is well accepted in Australia and the company have locked more than ten clients there. This new client purchased a whole powder Filling line (Model: PFL-B), including:

- Unscrambler Machine for PET Jars

- Powder Feeding Machine (Screw Conveyor)

- Automatic Powder Filling Machine (Linear)

- Automatic Capping Machine

- Aluminum Foil Sealing Machine (Optional)

- Automatic Labeling Machine

- Date/Code Printer

New Client with Common Pursuit

The client is one of Australia’s Leading Health Supplement manufactures, supplies health food and supplement retailers across Australia and on an international basis, and provides a wide range of services Including: Contract manufacturing, Private labelling, Wholesale & Distribution, and Packaging and Processing. It works effectively and efficiently as a professional food contract manufacturer, offering services in formulating, blending and packing of dry food and nutraceutical powders.

The client specializes in new product development and custom formulations to suit individual needs using only the highest quality ingredients. “We keep the process simple, taking care of everything from start to finish”.

Likewise, Uniaote is devoted to innovation and strives to better meet and exceed clients’ diverse product needs by providing designs that are exactly suited to their requirements. With similar business philosophy, Uniaote and the client reached agreement and become business partners.

Superb Fully-Automatic Powder Filling Production Line

As a matter of fact, the new production line is customized for this client. The bottleneck diameter is 123mm, an extra-large size. The production line composed of stainless steel, in addition to the remark material. All machine construction is in accordance with food hygiene standards chosen design. The entire production line equipment in accordance with GMP standards for the design specifications, consistent with national food hygiene requirements. Stainless steel used for manufacturing of the auger powder filling machines facilitate the longer life span and convenient maintenance.

Truly fully automated assembly line operation, ensure that the entire production process, staff will not touch the product, the production process is completely clean, more reliable product quality. The inner wall of the container in contact with the material are polished, frequently washable structure have adopted the easy disassembly parts is connected, ensure the turn shift or change raw materials easy to handle and health. Can helps plant design engineering programs to provide free technical support.

The fully-automatic powder filling production line was later exported and arrived in Griffith last month, Uniaote engineer are invited to Australia for production line commissioning and staff training.

Excellence and Customized Solutions

The global auger powder filling machines market is heavily influenced by advancement and technological revolutions in the packaging market in regions with high technology exports. Zhengzhou Uniaote Machinery Co., Ltd founded in 2001, is located in Zhengzhou, Henan province, the geographical center of China. The company is ideally situated with easy access to aviation, rail and truck transport services.

Uniaote designs and manufactures fully automated powder, granule and liquid product filling machines. The company is a well-established packing and filling machinery manufacture with a complete suite of production lines, including automatic, semi-automatic and manual solutions.

Global demand for packaging of food products has created substantial market opportunities for filling machines companies. Uniaote’s packing and filling machines are winning increasing attention from international companies because of its superb quality.

In the past six months, three Sets of fully-automatic powder filling production lines delivered to Australia, and a fully-automatic auger powder filling production line exported to Germany, a fully-automatic auger powder filling production line to Malaysia. But not only powder filling machines.

Taka Chang, International Trade Director at Uniaote, commented, “our packing and filling machines are gaining attention in world market. The packaging speed and load capacity of our auger powder filling machines is outstanding.

“‘There is no best, only better’ are not just words to us but a way of life. Uniaote are able to better meet and exceed clients’ diverse product needs by providing designs that are exactly suited to their requirements. Clients’ satisfaction is our motivation.

“Uniaote are specialized in machines for food packing, including milk powder, coffee, tea, spices and condiments, soup mixtures, meat powders, etc. We encourage you to bring your filling needs to us and give us the opportunity to provide you with exactly what you need. We know that your products and business are valuable and when you choose one of our systems you are making a choice of guaranteed excellence,” Mr. Chang said.

Uniaote Email: [email protected].